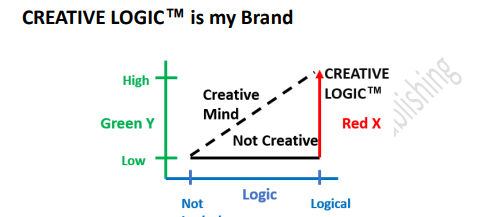

CREATIVE LOGIC BIRTH Dorian Shainin told me; ‘Tim, whenever you are stuck or confused, draw a picture.’ Many readers will […]

Blog

I was interviewed on a Podcast hosted by ViewPoint highlighting the skills of my friend Tim Nelson, discussing his skills […]

•

March 18, 2025

•

No Comments

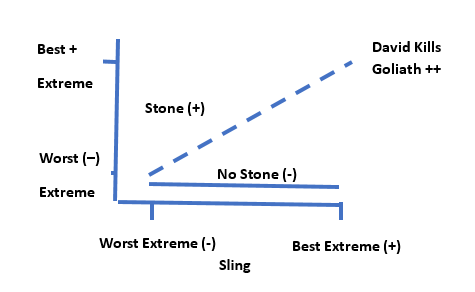

Creative Logic Blog Carl Bennett was very logical. He was the first statistician hired to build the Atom bomb. He […]

•

December 9, 2024

•

No Comments